Installation of heating systems: features and stages

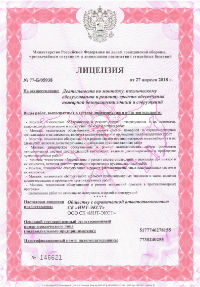

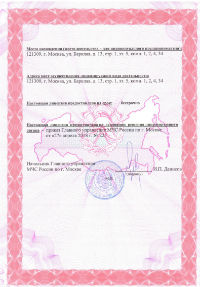

The heating system design requires performance of a wide range of works, under which the main principle is to adhere to a clear sequence, as well as to comply with applicable construction laws and regulations. Due to high degree of labor intensity and complexity, the need for specialized equipment, knowledge and skills, installation of the heating system should be performed by specialists with appropriate experience.

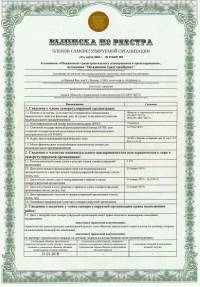

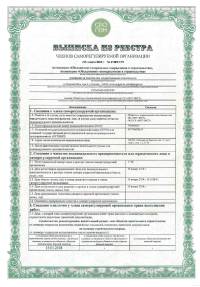

Int-Ext Company performs installation of heating systems at the highest professional level, delivering the full range of necessary works for office and shopping centers, restaurants, warehouses and other industrial or administrative facilities.

Stages of work

Installation of heating systems is carried out in several stages:

Design. The project starts with visit of Int-Ext representative to the site to assess the situation and discuss the details with the client. Our specialists design the heating system based on the pre-held hydraulic and thermal calculations in full compliance with the applicable construction laws and regulations. Heating design consists of the following parts: explanatory note, installation plan, axonometric schemes, the list of the basic equipment and materials.

Selection of equipment and materials. Based on the approved documentation, a list of necessary materials and equipment (pipes, radiators, boilers, valves, etc.) is being drawn up. The selection process focuses on the relevant features of the site. For example, the boiler is acquired depending on the heat capacity necessary for the building, and the radiators are selected based on heat loss in the premises in which they are installed. The volume of the pipes is calculated taking into account the design developed with approximately 10% reserve. Heating installation costs are calculated at this stage.

Installation of boiler and boiler room equipment. The need for boiler room occurs when the gas boiler required power exceeds 60 kW. The boiler room is equipped in accordance with the fire safety requirements, and all the equipment contained in it should be simple for access for maintenance by the personnel. Apart from the boiler in the boiler room there are installed a pump for the heat transfer agent circulation, expansion tank, as well as devices for measurements and filtering to ensure the heating system offline operation.

Mounting of tubes. Pipeline installation requires heat risers, as well as intermediate switching nodes and their pulling to the heating system.

Installation of floor heat. The floor heat is laid over the engineering systems in the floor, which are covered with "black" screed of 3-7 cm height, or on the floor slab after carrying out heat insulation and waterproofing. As a heat insulation material can serve the expanded clay, foil insulating, foam polystyrene.

Installation of radiators. It is generally carried out after finishing the premises, close to door openings or under the windows, as the cold outside air flow comes from here.

Start-up and commissioning works. At the final stage of the heating system installation primarily there are conducted hydraulic tests: the system is pressurized - significantly higher than the normal operating value. It is considered a norm when the heating system operates for at least 15 minutes and at the same time shows the constant pressure. If this requirement is met, the specialists run the boiler. Only after setting the boiler in operation and carrying out the practical test of the entire system the work is considered completed.

Int-Ext specialists will develop a competent design and quick professional installation of the heating system, regardless of the task complexity and the area of the building.

Examples of our work

Request for Proposal

A request sent to Int-Ext company will not remain unanswered. We will quickly analyze it and get in touch with you to prepare a proposal as per your request. Please fill in the form below.